6 min read

3 Cyber Security Myths That Will Hurt Your Business This Year

Working amid the ever-changing currents of technology andcyber security, businesses often find themselves entangled in...

By: Vested Marketing Jun 9, 2022 5:55:56 PM

With new technologies creating an ever-rising demand for the materials used to make batteries, Direct Lithium Extraction is proving to be the innovative process in the mining industry. This is a process that can provide the materials needed to shape the lithium market.

Lithium is an imperative substance used in the manufacturing of batteries. Our global demand for lithium may double in the next 5 years, and then double once again in the following 5 years.

Besides the economic demand for lithium increasing, there is also an increasing awareness and public outcry for environmentally friendly practices surrounding industrial processes, such as mining lithium.

Whether or not we can meet the demand for lithium will depend on having an innovative solution to produce the base materials needed.

Direct Lithium Extraction is the solution that can satisfy both economic and environmental concerns while providing the commercial-grade lithium needed to power the future of clean energy in a swift, low-cost manner.

Dr. John Burba (President & CEO of IBAT) invented the new Direct Lithium Extraction technology, which uses an improved selective absorbent and a radical engineering concept to produce high quality lithium.

This lithium extraction technology would be the lowest cost method of producing lithium using this proven and proprietary lithium extraction process from lithium baring brines.

This technology is expected to extract and produce lithium products (including lithium chloride, lithium carbonate, and lithium hydroxide) at costs similar to current low-cost lithium producers.

The process of extracting lithium has been made easier by amphibious vehicles that could both float and drive on land, as well as the invention of more efficient methods to purify it from its ore.

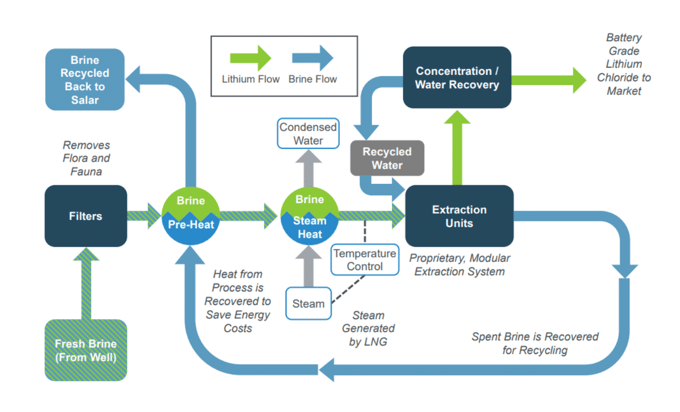

Direct Lithium Extraction uses a process that involves a highly selective absorbent to extract lithium from brine water. The solution extracted from the brine water is then polished of impurities to yield high-grade Lithium Carbonate and Lithium Hydroxide.

What makes Direct Lithium Extraction different from other methods is that it rejects critical impurities, yielding a higher quality product.

IBAT’s proprietary polishing technology reduces these impurities to less than 1ppm in the product LiCl stream. This step allows IBAT and its partners to produce lithium carbonate and lithium hydroxide with battery-grade purity or higher.

IBAT’s proprietary polishing technology reduces these impurities to less than 1ppm in the product LiCl stream. This step allows IBAT and its partners to produce lithium carbonate and lithium hydroxide with battery-grade purity or higher.

.png?width=221&name=economic%20(1).png)

IBAT’s modular plant design allows rapid placement at brine resources, minimizing capital costs, as well as construction and start-up time. The estimated installation and start-up time is currently less than one year.

IBAT’s novel process and control system leads to low operating costs with the total estimated capital costs being less than half of the traditional plant costs.

IBAT’s unique Selective Absorption technology is very environmentally friendly, eliminating solar evaporation ponds, salt piles, and lime plants, which not only preserves and protects the Earth for the wildlife and indigenous peoples who rely on natural resources for survival.

The technology also has another environmental advantage by rejecting impurities such as magnesium, calcium, sulfate, borate, and transmission metals.

To add to this, over 98% of the process water used by the plant is recycled using water control and recovery technology.

Direct Lithium Extraction is an innovative process that satisfies both economic and environmental concerns and provides commercial-grade lithium using a quick and low-cost method.

As the world moves toward a future of clean and sustainable energy, many global industries (from cryptocurrency tokens to energy sectors) are resonating with their markets to achieve a more environmentally friendly world.

From transportation to technology, even cryptocurrency (such as LITH Token), disaster recovery services and industrial waste cleaning are pivoting to work towards a future of sustainability.

International Battery Metals and Direct Lithium Extraction drive the future of clean energy.

![]() As a certified HubSpot Partner Agency, we not only understand the benefits of using the inbound marketing platform to increase traffic and engagement, improve SEO, generate leads, design effective websites and boost sales, we know how to make it happen.

As a certified HubSpot Partner Agency, we not only understand the benefits of using the inbound marketing platform to increase traffic and engagement, improve SEO, generate leads, design effective websites and boost sales, we know how to make it happen.

We are inbound marketing experts, SEO gurus and top-notch website developers.

Our team of Engineers Turned Marketers can help get you noticed - for a more innovative and effective way to reach customers, or provide a more seamless way for companies to find your services. Inbound Marketing has no limit to industry, serving from Crypto & NFT, mining, oil and gas, technology & automation, engineering, technology, construction, healthcare, to industrial & manufacturing.

6 min read

May 20, 2024 Vested Marketing

Working amid the ever-changing currents of technology andcyber security, businesses often find themselves entangled in...

5 min read

May 17, 2023 Vested Marketing

When you're looking for the best metal fabrication company for your specialized project in the oil and gas industry,...

6 min read

Dec 22, 2022 Vested Marketing

It may be going farther than some would like to say that Industry 4.0 is yet another industrial revolution. But call it...