6 min read

3 Cyber Security Myths That Will Hurt Your Business This Year

Working amid the ever-changing currents of technology andcyber security, businesses often find themselves entangled in...

By: Vested Marketing May 17, 2023 10:21:51 AM

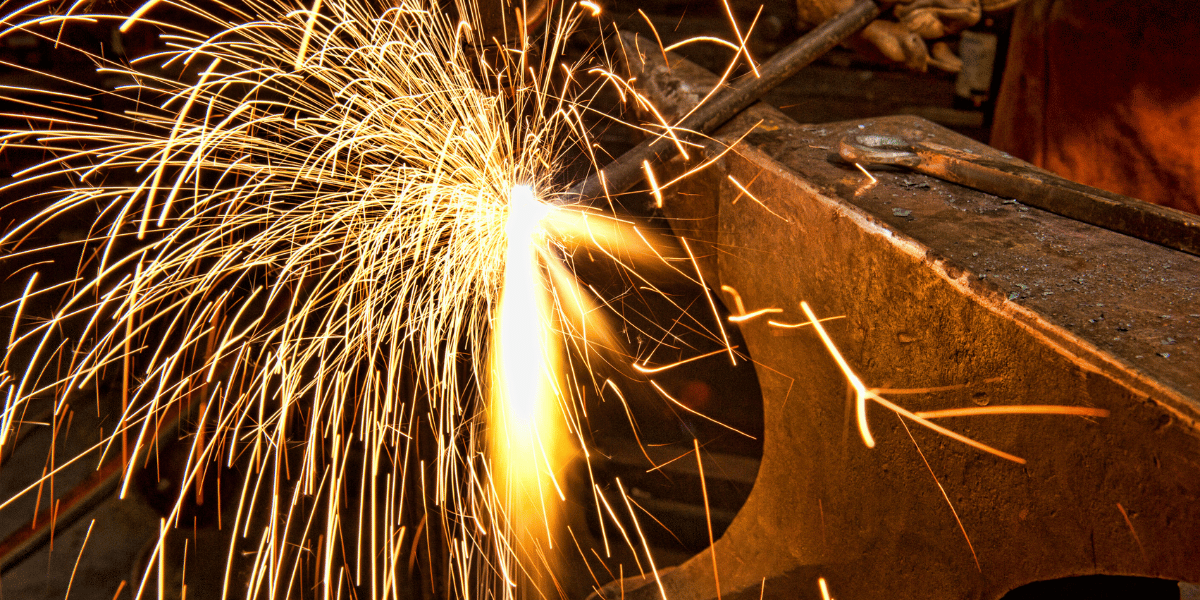

When you're looking for the best metal fabrication company for your specialized project in the oil and gas industry, there are four main requirements that they must meet: industry standards, quality assurance and safety programs, experience, and on-time delivery.

If a metal fabrication shop can meet all the below requirements, then you can be sure that you're working with a top-tier metal fabrication company!

When it comes to metal fabrication in the oil and gas industry, meeting industry standards is essential for providing a quality product. Companies should be certified by organizations such as the American Society of Mechanical Engineers (ASME), Det Norske Veritas (DNV), American Institute of Steel Construction (AISC), and American Bureau of Shipping (ABS).

These industry certifications can help ensure that the finished product meets all safety and quality standards, so it's important to make sure your metal fabrication company is certified by one or more of these organizations.

The American Society of Mechanical Engineers (ASME) is a professional organization that provides certification for companies that fabricate metal products. The ASME certification process is voluntary, but it is widely recognized as an indication of a company's commitment to quality and safety.

ASME certification is granted by the Board of Boiler and Pressure Vessel Inspectors (BBPVI). To become certified, a company must submit an application documenting its experience, quality control procedures, and safety record. The BBPVI then conducts on-site audits of the company's facilities and reviews its performance history. If the company meets all the criteria, it is granted an ASME certificate.

The benefits of ASME certification include improved customer confidence, greater access to markets, and increased credibility with suppliers. In addition, certified companies are subject to periodic audits to ensure they maintain their standards. As a result, ASME certification can be seen as a mark of excellence in the metal fabrication industry.

It's also important to make sure that your chosen metal fabrication company has a quality assurance process in place. This process should involve testing for defects, precision measurements, and other types of quality checks. Ask to see their quality control documentation and procedures before you start working with them.

Safety is of paramount importance in metal fabrication, and the best metal fabrication services and shops will have stringent safety standards in place. These standards should include regular inspections to ensure that all equipment is properly maintained, as well as proper training for employees on the safe use of tools and machinery.

In addition, the shop should also have processes in place to prevent accidents such as fire or chemical spills and be able to provide proof that they are compliant with relevant regulations and codes of practice. By ensuring a high level of safety at their facility, these shops can help protect both their workers and customers from potential harm.

When it comes to complex projects like metal fabrication in the oil and gas industry, experience is essential. Look for a company that has years of experience in this field, expertise with various exotic metals and ask for references to get an idea of the type of work they've done in the past.

As a business, you want to be able to count on the quality of the workmanship that you receive. That’s why it’s so important to find a company with a proven track record of quality workmanship.

At its core, customer service is about creating relationships with customers. It’s about understanding their needs and desires and then going above and beyond to meet or exceed their expectations. Good customer service requires a deep commitment to putting the customer first in everything you do.

Finally, it's important to make sure that your chosen metal fabrication company can deliver the product on time. This is especially crucial if the project is part of a larger project and any delays could cause a domino effect. Discuss the delivery timeline before you start your project and make sure that the company has a plan in place to meet these deadlines.

Have questions about fabrication? We know people in the industry! Connect with us to chat more.

https://www.cypressfabrication.com/insights/top-4-requirements-of-a-metal-fabrication-shop

![]() As a certified HubSpot Partner Agency, we not only understand the benefits of using the inbound marketing platform to increase traffic and engagement, improve SEO, generate leads, design effective websites and boost sales, we know how to make it happen.

As a certified HubSpot Partner Agency, we not only understand the benefits of using the inbound marketing platform to increase traffic and engagement, improve SEO, generate leads, design effective websites and boost sales, we know how to make it happen.

We are inbound marketing experts, SEO gurus and top-notch website developers.

Our team of Engineers Turned Marketers can help get you noticed - for a more innovative and effective way to reach customers, or provide a more seamless way for companies to find your services. Inbound Marketing has no limit to industry, serving from Crypto & NFT, mining, oil and gas, technology & automation, engineering, technology, construction, healthcare, term life insurance, to industrial & manufacturing.

6 min read

May 20, 2024 Vested Marketing

Working amid the ever-changing currents of technology andcyber security, businesses often find themselves entangled in...

5 min read

May 17, 2023 Vested Marketing

When you're looking for the best metal fabrication company for your specialized project in the oil and gas industry,...

6 min read

Dec 22, 2022 Vested Marketing

It may be going farther than some would like to say that Industry 4.0 is yet another industrial revolution. But call it...